2W21 Brass or Stainless Steel 12V Solenoid Valve

2W21 Direct Lifiting Diaphragm 12V Solenoid Valve applied to low pressure system with harder valve body; Import sealing material, zero lekage, low power consumption; Adapt new technology and high frequency of flying lead coil, not getting hot while long time using, low temperature changeing;

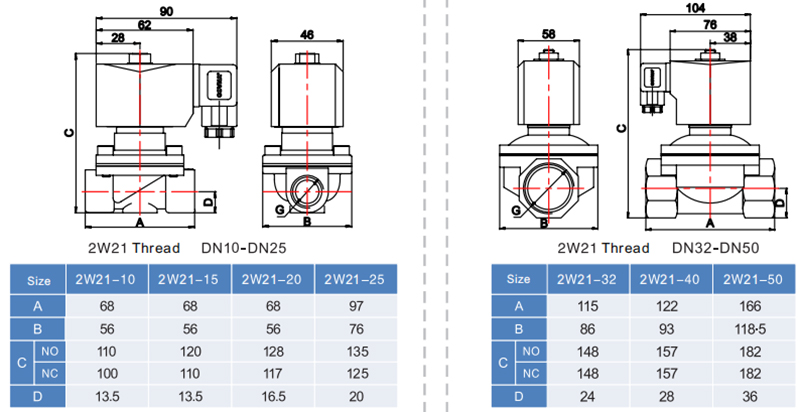

- Model: 2W21

- Size Range: 1/2” to 2”

- Pressure Range: 0-1.0 MPa (10 bar)

- Material: Brass, Stainless steel

| Port Size | 3/8”~2” | Orifice(mm) | 15, 20, 25, 32, 40, 50 |

| Port Thread | BSPP, BSPT, NPT, FLANGE | Function | Normally closed or opened |

| Pressure | 0-1.0 MPa (10 bar) | Voltage | DC-12V, 24V; AC-24V, 120V, 240V/60Hz; 110V, 220V/50Hz |

| Temperature of media | -10~100℃ (14℉ to 212℉) | Suitable Media | Water, gas, oil, etc |

| Material | Brass, Stainless Steel | Sealing Material | NBR, VITON, PTFE, EPDM |

| Coil | S51B,30VA(AC),24W(DC),IP65,100%ED | ||

| Coil | SD01B,28VA(AC),36W(DC),IP65,100%ED | ||

- 2W21 12V solenoid valve are automatic solenoid valves for gas water, oil. They are easy and safe to operate.

- This normally used solenoid valve can be used in many fields, usch as, Air, City Gas, Water, Oil, Petroleum, Environemtal Protection, etc.

- Suitable for low head and zero head applications with a coupled diaphragms

| Port Size | 3/8”~2” | Orifice(mm) | 15, 20, 25, 32, 40, 50 |

| Port Thread | BSPP, BSPT, NPT, FLANGE | Function | Normally closed or opened |

| Pressure | 0-1.0 MPa (10 bar) | Voltage | DC-12V, 24V; AC-24V, 120V, 240V/60Hz; 110V, 220V/50Hz |

| Temperature of media | -10~100℃ (14℉ to 212℉) | Suitable Media | Water, gas, oil, etc |

| Material | Brass, Stainless Steel | Sealing Material | NBR, VITON, PTFE, EPDM |

| Coil | S51B,30VA(AC),24W(DC),IP65,100%ED | ||

| Coil | SD01B,28VA(AC),36W(DC),IP65,100%ED | ||