COVNA 2W21 Plastic PVC Water Solenoid Ball Valve

COVNA 2W21 series plastic solenoid ball valve, the action mode is direct pull diaphragm type, the switch mode can be normally open, the valve body material can be brass, stainless steel, characterized by large flow, zero pressure start, widely used in the automatic control of pipeline fluid with zero pressure differential start. It applied to low pressure system. Available in 12vdc, 24vdc, 110vac and 220ac.

COVNA provide solenoid valve in stainless steel, pvc and brass material in all pressure and all voltage.

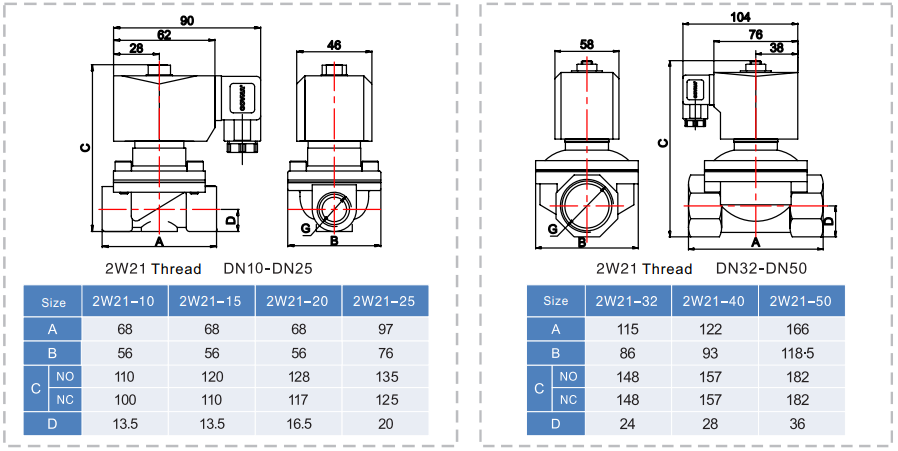

- Model: 2W21 PVC

- Size Range: 1/2”~2”

- Pressure Range: 0.0MPa-1.0 MPa

- Material: Brass, Stainless steel, UPVC

COVNA 2 Way 2 Position Direct Acting Diaphragm Solenoid Ball Valve

- Features: Zero Leakage, Waterproof, High Pressure, High Temperature, etc

- Size Range: 3/8″ to 2″. Special size could be customized.

- Material: Brass, Stainless Steel and Plastic

- Suitable Medium: Water, Oil, Air, Gas and so on

- Light weight, low cost and durable. Widely used in car wash system, water treatment, and other applications.

- Pressure Range: Normal Pressure(0-10bar), High Pressure(0-250bar)

- Temperature: Normal Temperature(-10℃~80℃), Medium Temperature(-10℃~120℃), High Temperature(-10℃~180℃)

| Port Size | 3/8”, 1/2″, 3/4″, 1″, 1¼”, 1½”, 2″ | Orifice(mm) | 15, 20, 25, 32, 40, 50 |

| Port Connection | BSPP,BSPT, NPT, Flange | Function | Normally closed or opened |

| Pressure | 0.00MPa-1.0MPa | Voltage | DC-12V, 24V, AC-24V, 120V, 240V/60Hz; 110V,220V/50Hz |

| Temperature of media | NBR Seal: 0~80℃

EPDM Seal: 5~190℃ |

Suitable Media | Alkali Acid and salt etc |

| Material | UPVC, CPVC | Sealing Material | EPDM, VITON,NBR, PTFE |

| Coil | YC1B , 15W ( AC ) , 16W ( DC ) | ||

| Coil | YELB, start at 200W, maitain at 5W(AC),28W(DC) | ||

| Coil | YF1B, start at 350W, maitain at 10W(AC), start at 75W,maitain at 25W(DC) | ||

| Port Size | 3/8”, 1/2″, 3/4″, 1″, 1¼”, 1½”, 2″ | Orifice(mm) | 15, 20, 25, 32, 40, 50 |

| Port Connection | BSPP,BSPT, NPT, Flange | Function | Normally closed or opened |

| Pressure | 0.00MPa-1.0MPa | Voltage | DC-12V, 24V, AC-24V, 120V, 240V/60Hz; 110V,220V/50Hz |

| Temperature of media | NBR Seal: 0~80℃

EPDM Seal: 5~190℃ |

Suitable Media | Alkali Acid and salt etc |

| Material | UPVC, CPVC | Sealing Material | EPDM, VITON,NBR, PTFE |

| Coil | YC1B , 15W ( AC ) , 16W ( DC ) | ||

| Coil | YELB, start at 200W, maitain at 5W(AC),28W(DC) | ||

| Coil | YF1B, start at 350W, maitain at 10W(AC), start at 75W,maitain at 25W(DC) | ||